- Home

- About Us

- Our Services

- Parts Screening & Testing

- EEE Parts Management

- Destructive Physical & Failure Analysis

- Counterfeit Parts Analysis, Screening, & Detection

- RF Testing, Screening, & Qualification

- Custom Assembly, Packaging & Qualification

- Patented DPEM Process for Die Removal

- Cryogenics Test Lab

- Trusted Semiconductor Die/Wafer Source

- QML Memory

- Obsolete Parts Replacement

- Quality

- News

- Contact

- Search

Call Us Today!: 805-581-9200

Call Us Today!: 805-581-9200

- Home

- About Us

- Our Services

- Parts Screening & Testing

- EEE Parts Management

- Destructive Physical & Failure Analysis

- Counterfeit Parts Analysis, Screening, & Detection

- RF Testing, Screening, & Qualification

- Custom Assembly, Packaging & Qualification

- Patented DPEM Process for Die Removal

- Cryogenics Test Lab

- Trusted Semiconductor Die/Wafer Source

- QML Memory

- Obsolete Parts Replacement

- Quality

- News

- Contact

- Search

- Home

- About Us

- Our Services

- Parts Screening & Testing

- EEE Parts Management

- Destructive Physical & Failure Analysis

- Counterfeit Parts Analysis, Screening, & Detection

- RF Testing, Screening, & Qualification

- Custom Assembly, Packaging & Qualification

- Patented DPEM Process for Die Removal

- Cryogenics Test Lab

- Trusted Semiconductor Die/Wafer Source

- QML Memory

- Obsolete Parts Replacement

- Quality

- News

- Contact

- Search

Custom Assembly, Packaging and Qualification

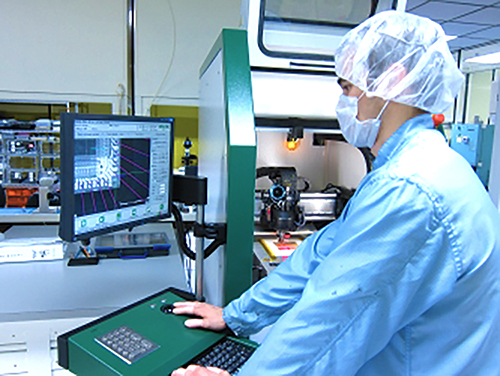

DPACI specializes in providing Turn-Key Solutions. We offer comprehensive manufacturing, assembly, qualification, testing, and certification of high reliability EEE components. We have a dedicated, self-contained Class 10,000 clean room with Class 100 laminar flows certified to QML Q (Military) and V (Space) levels to perform all assembly operations from wafer processing to final hermetic package seal

Packaging and Assembly of custom microcircuits and hybrids conforming to Class “Q”, “H” and Class “V”, “K” requirements of MIL-PRF-38535, MIL-PRF-38534 and MIL-STD-883 is the initial phase of a Turn-Key Solution effort.

Screening, Qualification, and Testing/Analysis ensures that the product to meets mission critical requirements of customer applications. Experienced quality control personnel in our AS9100 infrastructure are involved in every step of the process flow, from first article testing to final inspection with total traceability, produces higher yields with precision and repeatability.

Military and Space

We perform all manufacturing processes required to package monolithic microcircuits in conformance with DEFENSE LOGISTICS AGENCY (DLA) approved procedures and processes under our MIL-PRF-38535 QML “Q” Level – Military Grade and “V” level – Space Grade manufacturing lines.

In-Process Monitoring Throughout

In-process monitors such as destructive and non-destructive bond pull, die stud pull, 100% visuals, first article electricals, residual gas analysis and hermeticity are carried out as routine in-line assembly processes in our clean room facility. Using modern assembly equipment, highly skilled personnel, rigorous discipline with expert training and testing certifications, DPACI offers a unique Turn-Key Solution to the high reliability custom parts industry.

The Defense Logistics Agency (DLA) Certified team at DPACI performs all part assembly, qualification, screening, testing and analysis in-house, under one roof to facilitate throughput and visibility for our customer’s mission critical requirements.