- Home

- About Us

- Our Services

- Parts Screening & Testing

- EEE Parts Management

- Destructive Physical & Failure Analysis

- Counterfeit Parts Analysis, Screening, & Detection

- RF Testing, Screening, & Qualification

- Custom Assembly, Packaging & Qualification

- Patented DPEM Process for Die Removal

- Cryogenics Test Lab

- Trusted Semiconductor Die/Wafer Source

- QML Memory

- Obsolete Parts Replacement

- Quality

- News

- Contact

- Search

Call Us Today!: 805-581-9200

Call Us Today!: 805-581-9200

- Home

- About Us

- Our Services

- Parts Screening & Testing

- EEE Parts Management

- Destructive Physical & Failure Analysis

- Counterfeit Parts Analysis, Screening, & Detection

- RF Testing, Screening, & Qualification

- Custom Assembly, Packaging & Qualification

- Patented DPEM Process for Die Removal

- Cryogenics Test Lab

- Trusted Semiconductor Die/Wafer Source

- QML Memory

- Obsolete Parts Replacement

- Quality

- News

- Contact

- Search

- Home

- About Us

- Our Services

- Parts Screening & Testing

- EEE Parts Management

- Destructive Physical & Failure Analysis

- Counterfeit Parts Analysis, Screening, & Detection

- RF Testing, Screening, & Qualification

- Custom Assembly, Packaging & Qualification

- Patented DPEM Process for Die Removal

- Cryogenics Test Lab

- Trusted Semiconductor Die/Wafer Source

- QML Memory

- Obsolete Parts Replacement

- Quality

- News

- Contact

- Search

Patented DPEM Process for Die Removal

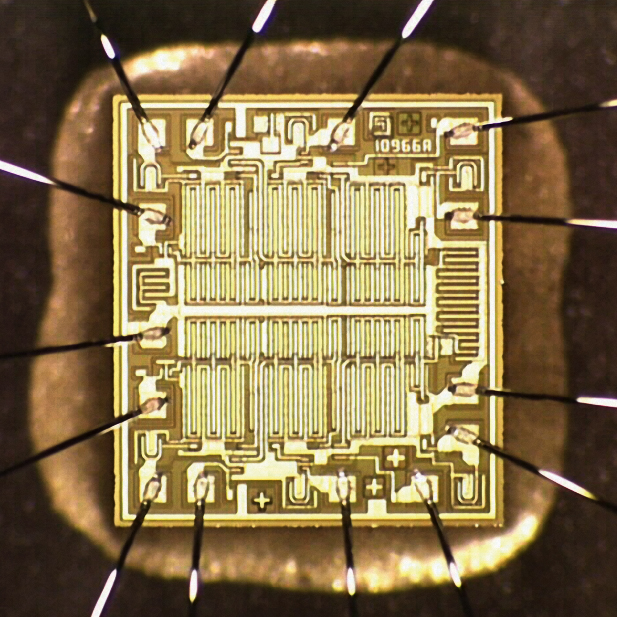

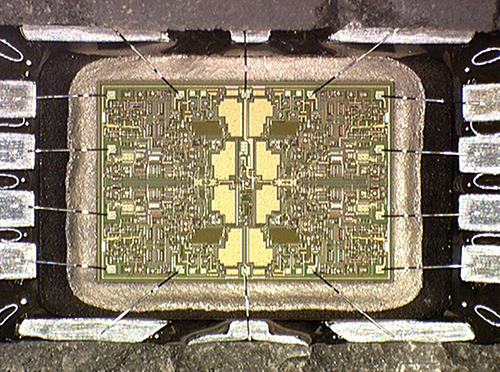

DPEM (Decapsulate Plastic Encapsulated Module) is DPACI’s patented Turn-Key Solution to replacement of obsolete high reliability devices in legacy systems. From dissolving the plastic encapsulation of a semiconductor device to re-bonding new wires onto a chip or package lead frame, complete solutions are offered. DPACI retains reliability test data as well as customer testimonials for the process and can share this information on a need-to-know basis.

This cost-effective proprietary solution of “Die Harvesting” allows us to provide obsolete or hard-to-find ICs that are no longer manufactured in the required pin-outs or hermetic packages. Our patented DPEM “Die Extraction” process of allows us to remove a die from an existing plastic part and repackage it into a ceramic, metal, or hybrid package. As part of our DPEM process, we also screen the complete components to MIL-STD-883 Class B or Class S procedures.

DPEM parts can satisfy form, fit, function, quality, and reliability requirements for replacement of military or aerospace components. These replacement parts can save millions of dollars over reinvention and manufacturing a military grade device for boards or assemblies. In addition, the delivery is virtually immediate if the plastic COTS part is readily available. We can provide engineering units within days as candidates for your evaluation. DPACI’s DPEM process always include electrical test with read and recorded data to validate authenticity of the dice.

DPACI can also remove dice from some ceramic packages in a similar process called DCEM. These dies can also be used for hybrids or MCM needs. DPEM process is also useful for IC failure analysis. We selectively etch and remove the top of a plastic IC leaving all bond wires intact, exposing the die for failure analysis.