- Home

- About Us

- Our Services

- Parts Screening & Testing

- EEE Parts Management

- Destructive Physical & Failure Analysis

- Counterfeit Parts Analysis, Screening, & Detection

- RF Testing, Screening, & Qualification

- Custom Assembly, Packaging & Qualification

- Patented DPEM Process for Die Removal

- Cryogenics Test Lab

- Trusted Semiconductor Die/Wafer Source

- QML Memory

- Obsolete Parts Replacement

- Quality

- News

- Contact

- Search

Call Us Today!: 805-581-9200

Call Us Today!: 805-581-9200

- Home

- About Us

- Our Services

- Parts Screening & Testing

- EEE Parts Management

- Destructive Physical & Failure Analysis

- Counterfeit Parts Analysis, Screening, & Detection

- RF Testing, Screening, & Qualification

- Custom Assembly, Packaging & Qualification

- Patented DPEM Process for Die Removal

- Cryogenics Test Lab

- Trusted Semiconductor Die/Wafer Source

- QML Memory

- Obsolete Parts Replacement

- Quality

- News

- Contact

- Search

- Home

- About Us

- Our Services

- Parts Screening & Testing

- EEE Parts Management

- Destructive Physical & Failure Analysis

- Counterfeit Parts Analysis, Screening, & Detection

- RF Testing, Screening, & Qualification

- Custom Assembly, Packaging & Qualification

- Patented DPEM Process for Die Removal

- Cryogenics Test Lab

- Trusted Semiconductor Die/Wafer Source

- QML Memory

- Obsolete Parts Replacement

- Quality

- News

- Contact

- Search

IN THE NEWS...

DPA Components International, Simi Valley

Selected for Virgin Galactic, LLC's "Approved Supplier List"

June - 2022

DPA Components International - DPACI has just been added to Virgin Galactic’s Approved Supplier List. DPACI understands the high level of expectations Virgin Galactic has for its Suppliers and DPA Components International seeks to exceed those expectations with all of the services and products we provide. We are thankful for this recognition from Virgin Galactic and look forward to working with them moving forward.

DPA Components International, Simi Valley

Pursues ISO/IEC 17025:2017 Accreditation

MAY - 2022

To help meet the new DLA Land and Maritime testing expectations for Manufacturers and Distributors of QTSL Products, DPA Components International – DPACI has signed with Perry Johnson Laboratory Accreditation, Inc to perform services for ISO/IEC 17025:2017 Accredition for AS6171 Test Methods /1 through /11. DPA Components International has been providing testing services to the AS6171 Standard for many years and the pursuit of this Accreditation reflects DPA Components International’s continued commitment to supporting all of our customers testing requirements and to assist in preventing Suspect/Counterfeit (SC) Electrical, Electronic, and Electromechanical (EEE) parts from entering the aerospace supply chain, posing significant performance, reliability, and safety risks.

For over 40 years DPA Components International - DPACI has been a key provider of testing, and analysis of electronic parts for mission critical systems in the aerospace, space, and military industries. DPACI operates out of our state-of-the-art 40,000 square foot facility in Simi Valley, California. Our facility was designed and built from ground up to provide manufacturing, test and analytical services within a comprehensive parts reliability center under one roof.

DPACI’s “Total Solutions Approach” provides an integrated team within one facility, to ensure that quality is part of the initial design and development and continues through all phases of production, testing and certification. This minimizes the risk and logistics in a program, resulting in “Better Value” for our customers.

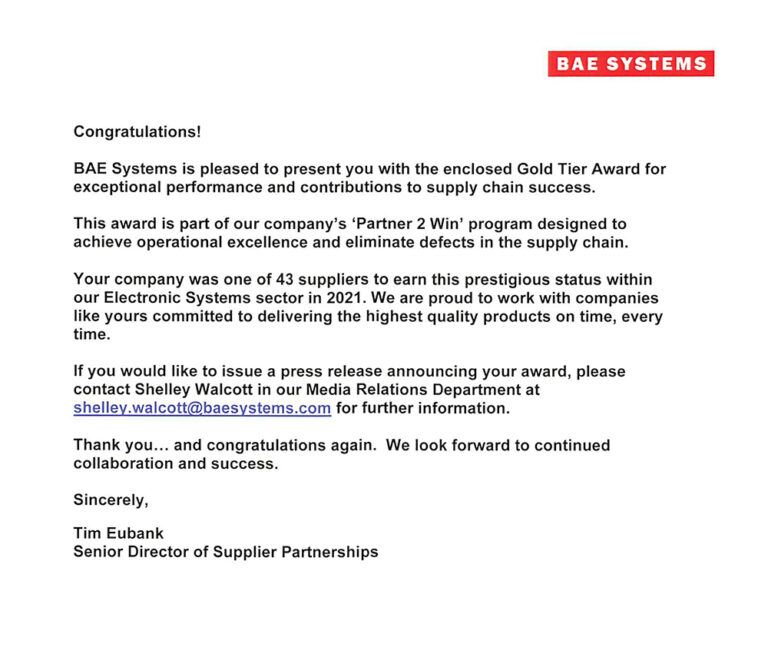

DPA Components International, Simi Valley

Once Again Receives Gold Tier Award from BAE Systems

MARCH - 2022

Once again , DPA Components International receives BAE Systems’ Gold Tier Award for exceptional performance and contributions to supply chain success. This award is part of BAE’s “Partner 2 Win” program designed to achieve operational excellence and eliminate defects in the supply chain.

DPA Components International was one of only 43 Suppliers in BAE Electronic Systems sector for the year 2021.

We sincerely appreciate this recognition as a valued supplier for BAE Systems. DPA Components International strives to provide the best services to all of our customers and work as a team to make sure our customer’s expectations are always exceeded.

Thank you again BAE Systems for your business and confidence in DPA Components International.

DPA Components International, Simi Valley

Awarded $3M Contract from US Air Force

SEPTEMBER - 2020

DPA Components Int’l was awarded a $3 million contract from the Air Force to automate their Die Extraction and Remanufacturing (DPAM) process that is used for replacement spares, which normally would need less than a dozen at a time and a single order could easily be satisfied by a heavily manual procedure. However, with a series of spare orders involving 50 to 100 ICs, the current manual procedure could not provide a timely delivery. It is necessary to create a DPAM methodology with existing industry developed semi-automated equipment to produce reliably with mechanical, laser, ultrasonic, etching and microwave technology to reliably extract the die from a plastic part and repackage into a form, fit, and function package meeting the footprint of the obsolete part. The goal is to accomplish the remanufacturing average time in one-fourth the manual process time for a high quantity remanufactured production semiconductor.

DPA Components International, Simi Valley

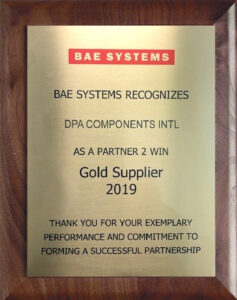

Receives Gold Tier Award from BAE Systems

JUNE - 2020

BAE Systems was pleased to present DPA Components International with the Gold Tier Award for exceptional performance and contributions to supply chain success.

This award is part of BAE’s company’s ‘Partner 2 Win’ program designed to achieve operational excellence and eliminate defects in the supply chain.

DPA Components International was one of 43 suppliers to earn this prestigious status from a pool of more than 2,200 suppliers within BAE’s Electronic Systems sector in 2019.

DPA Components International, Simi Valley

Partnership with Infineon/Cypress Semiconductor Corporation

on Space Level Memory Products

APRIL - 2020

DPACI is pleased to announce the continue partnership with Infineon/Cypress Semiconductor on a family of Synchronous Static and Flash Memories for space level requirements. The memory sizes include:

2 megabytes*

4 megabytes*

16 megabytes*

72 megabytes*

144 megabytes*

288 megabytes**

256 megabytes**

512 megabytes**

*QML V level of MIL-PRF-38535

** QML V by fiscal year 2022.

DPA Components International, Simi Valley

DPACI’s DPEM Patent product passed

MIL-PRF-38535 for Class B and Class S Level test requirements in

US Air Force

Award Reliability Study.

JANUARY - 2020

Due to the obsolescence created by technical advancement in semiconductor electronic parts, an effective and quick reaction solution is needed to bridge existing legacy systems to new designs and platforms. DER (Die Extraction and Reassembly) has been introduced to the industry in the 1990’s and has solved many small scale obsolescence problems with DPA Components International's DPEM Patent. In this study DPACI selected five (5) different obsolete IC types of different technology for the DER/DPEM process to prove it will yield reliable products meeting MIL-STD-883 and by using existing processes procedures developed over 20 years. The study shows that the processes developed by DPACI’s DPEM Process can remove dice from precursor plastic parts of different technologies, repackage them into standard MIL-STD-1835 hermetic packages, test and qualify to the rigorous Class B and Class S level assembly and screening of MIL-PRF-38535 and MIL-STD-883 to be a viable form-fit function turn-key solution to obsolescence.