- Home

- About Us

- Our Services

- Parts Screening & Testing

- EEE Parts Management

- Destructive Physical & Failure Analysis

- Counterfeit Parts Analysis, Screening, & Detection

- RF Testing, Screening, & Qualification

- Custom Assembly, Packaging & Qualification

- Patented DPEM Process for Die Removal

- Cryogenics Test Lab

- Trusted Semiconductor Die/Wafer Source

- QML Memory

- Obsolete Parts Replacement

- Quality

- News

- Contact

- Search

Call Us Today!: 805-581-9200

Call Us Today!: 805-581-9200

- Home

- About Us

- Our Services

- Parts Screening & Testing

- EEE Parts Management

- Destructive Physical & Failure Analysis

- Counterfeit Parts Analysis, Screening, & Detection

- RF Testing, Screening, & Qualification

- Custom Assembly, Packaging & Qualification

- Patented DPEM Process for Die Removal

- Cryogenics Test Lab

- Trusted Semiconductor Die/Wafer Source

- QML Memory

- Obsolete Parts Replacement

- Quality

- News

- Contact

- Search

- Home

- About Us

- Our Services

- Parts Screening & Testing

- EEE Parts Management

- Destructive Physical & Failure Analysis

- Counterfeit Parts Analysis, Screening, & Detection

- RF Testing, Screening, & Qualification

- Custom Assembly, Packaging & Qualification

- Patented DPEM Process for Die Removal

- Cryogenics Test Lab

- Trusted Semiconductor Die/Wafer Source

- QML Memory

- Obsolete Parts Replacement

- Quality

- News

- Contact

- Search

Our DPA / FA Lab

DPACI's component analysis laboratory performs major analytical functions, such as destructive physical analysis, failure analysis, counterfeit analysis, and material analysis on components & devices. Our destructive physical analysis techniques are performed in accordance with standards and methods used in most military and space program requirements. Solutions for difficult production problems are resolved through our failure analysis procedures. We perform complete disassembly, testing, and inspection of all types of EEE components in conformance with exact customer design or process requirements. Standards mostly used in our DPA process are: MIL-STD-1580, SSQ25000, MIL-STD-883.

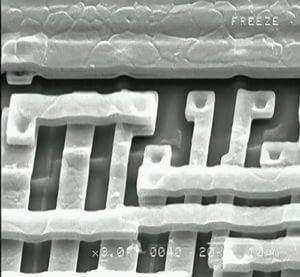

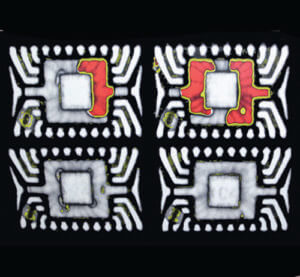

From removal of encapsulants to internal visual inspections after cross section, different types of operations are performed as a part of our Destructive Physical Analysis (DPA) process.

Types of Analysis We Perform

Our standard DPA program includes

Taking external/internal photos

Leak test

Electrical test

Delidding / Decapsulation

Bond pull testing

Scanning Electronic Microscope (SEM)

X-ray fluorescence (XRF)

Energy dispersive X-ray spectrometry (EDX)

C-mode Scanning Acoustic Microscopy (CSAM)

Cross section visual examination

Mechanical as well as environmental tests as applicable

Material analysis on any type of material, including continuous fiber reinforced composites, ceramics, and polymers

Particle impact noise detection (PIND)

Radiographic inspection

Die shear strength testing

Fourier transformation infrared spectroscopy (FITR)

These highly detailed processes of sample testing establishes a baseline specification and ensures that a high reliability component or device is fabricated to the required standards.

Scanning Electronic Microscope (SEM), X-ray fluorescence (XRF), energy dispersive X-ray spectrometry (EDX), and C-mode Scanning Acoustic Microscopy (CSAM) are used to perform in-depth failure and materials analysis on hermetic and plastic devices.

In addition to in-house support from the electrical test floor in validation of device functionality, we routinely provide electrical data for a device under failure analysis to the customer prior to opening or decapsulation

In addition to in-house support from the electrical test floor in validation of device functionality, we routinely provide electrical data for a device under failure analysis to the customer prior to opening or decapsulation